A New Affiliation: the UMass Chan Medical School

Although the development and production of RespiGam was completed under the management of MHRI, some confusion in the public arose about the role that the Massachusetts Department of Public Health played in the development and manufacturing of RespiGam. After much discussion, in August of 1996, the state of Massachusetts decided to transfer oversight of the Laboratories to the UMass Chan Medical School. The University and the Biologic Laboratories had, and still have, common research, academic, and health care missions. Under the management of UMass Chan, the Laboratories would maintain and cultivate their original public health mission to the residents of Massachusetts, while simultaneously expanding their ability to develop and manufacture products that could be used in a global manner. The state law to transfer the Laboratories to UMass Chan went into effect January 1, 1997.92

Interestingly, the Department of Public Health had previously attempted to create a more flexible management structure for the Biologic Laboratories in 1993. As a way to manage a variety of state administrative limitations and the increased demands from new rules and regulatory inspections by the FDA, the Department of Public Health and the Biologic Laboratories sought to develop a new governance model and establish the Massachusetts Biologics and Laboratory Sciences Institute (MBLSI). In this new model, MBLSI would operate under the governance of a Board of Directors consisting of public health and human services managers, as well as experts in the fields of pediatrics, medicine, and biotechnology. One of the major advantages MBLSI would have offered was the ability to form cooperative partnerships with private biotechnology companies to develop products that would benefit a wide variety of people, and be provided to Massachusetts residents for free, or at a small cost. In a presentation to the legislature’s Joint Committee on Health Care on March 14th, 1995, the advocates for MBLSI noted that “no single vaccine producer has access to all of the technologies needed to produce state-of-the-art vaccines and therefore numerous collaborations and strategic alliances have been formed among commercial vaccine manufacturers. By providing mechanisms for collaborating…the proposed legislation will ensure that the Biologic Laboratories will participate fully in the biotech revolution.” The financial benefits gained from new biologics and vaccine products that would come from these cooperative partnerships would pay for the future expenses of MBLSI. The bill to establish MBLSI, “An Act to Promote the Public Health,” was filed in January 1995, but never passed.93

for Biologic Laboratories

staff from DynPort, 2004

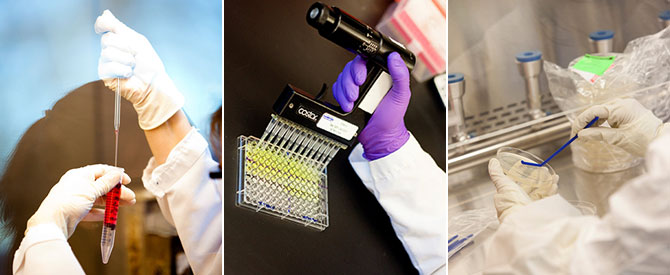

In 1996, Dr. Siber left the Biologic Laboratories to work for Wyeth Research, and Dr. Leszczynski served as Acting Director until Donna Ambrosino, M.D., a former Associate Professor at Harvard Medical School, was named the new Executive Director of the Biologic Laboratories in 1998. With a new leader came new scientific collaborations and partnerships to develop products that would benefit a wider range of people. For example, in 1998, the Biologic Laboratories collaborated with the Swiss Serum and Vaccine Institute to develop an acellular Pertussis vaccine. It also began another collaboration with the Unites States Army. In 1999, the Department of Defense requested bids for management of its smallpox Biologic Defense Program and sought a manufacturer for Vaccinia Immune Globulin (VIG). This ten year contract was awarded to DynPort LLC, and under the contract, the Biologic Laboratories manufactured VIG. Although relatively rare, people can have bad reactions to the smallpox vaccine; infusion with the immune globulins will treat these reactions. Dr. Leszczynski and the entire Biologic Laboratories team were later recognized in November 2002 for their efforts following the tragic events on September 11th, 2001 in a letter from Brigadier General Stephen V. Reeves. In his letter, Reeves thanked the Laboratories for its commitment to help the nation by developing and implementing “a concise strategy to manufacture” VIG.

Leszczynski from

Stephen V. Reeves,

Brigadier General, USA,

Program Officer for

Chemical & Biological

Defense,

dated November 15, 2002

Monoclonal Antibodies and a New Name: MassBiologics

In 2000, the UMass Chan Board of Trustees voted to authorize the Biologic Laboratories to enter into agreements with private companies and manufacture products that can be sold and marketed outside of Massachusetts; during that same year, the Laboratories received a hyperimmune globulin manufacturing contract from the biotechnology company Inhibitex. In 2001, the Laboratories entered into a collaborative agreement with Sunol Molecular Corporation to manufacture a monoclonal antibody to a target protein (tissue factor). Shortly after, the Laboratories accepted a contract to develop and manufacture two monoclonal antibodies to treat children who acquire certain strains of E. coli that are associated with hemorrhagic colitis. These strains are known as Shiga toxin producing E. Coli (STEC).94 Before this time, the Biologic Laboratories had only focused on developing and manufacturing broad-acting polyclonal antibodies (immune globulins). Polyclonal antibodies are derived from human plasma, which is a limited source, and in 2006, production of all blood and plasma products ceased at the Biologic Laboratories.95 Monoclonal antibodies, on the other hand, are laboratory-produced identical clones of immunized cells and can be made in large quantities.

An outbreak of Severe Acute Respiratory Syndrome (SARS), a serious viral respiratory illness, in 2003 put the Biologic Laboratories on alert. The first case of SARS, reported in Asia during February 2003, lead to a global outbreak.96 The Biologic Laboratories immediately began working with the NIH to develop a protective monoclonal antibody against SARS. A provisional patent for discoveries related to SARS monoclonal antibody was filed in October 2003.97 In order to make the monoclonal antibody, the Laboratories worked with transgenic mice provided by Medarex, a division of the pharmaceutical company Bristol-Myers Squibb. Transgenic mice contain “additional, artificially-introduced genetic material in every cell”98 and can be used to develop monoclonal antibodies.

The relationship with Medarex was not new to the Laboratories. Before the SARS outbreak, the Laboratories had begun work on a new monoclonal antibody to protect against clostridium difficile (C. difficile), which causes a devastating hospital-acquired infection that can cause severe diarrhea and, in some cases, necrosis of parts of the bowel. An agreement regarding C. difficile was signed in 2002 between Medarex and the Laboratories. In February 2004, the Laboratories filed for a provisional patent for C. difficile monoclonal antibody, and clinical trials began the same year. The resulting successful combination of two monoclonal antibodies was licensed to Merck in 2009. The patent was issued the following year. In 2010, a press release noted that when the monoclonal antibody combination was administered with standard antibiotics, the result was a reduced “recurrence of a debilitating form of diarrhea by 72 percent in patients enrolled in a Phase 2 clinical trial.”99 The development of the C. difficile monoclonal antibody was the first Biologic Laboratories-sponsored monoclonal antibody Investigational New Drug (IND) application. As defined by the FDA, an IND “is a request for authorization from the…[FDA] to administer an investigational drug or biological product to humans.”100

Thus, the beginning of the 21st century had brought a dramatic growth in staff, research, and production needs. As new products were being developed, the Biologic Laboratories staff grew to 300 people. To meet the growing demand and provide significant improvements in equipment and facilities, a new facility in nearby Mattapan was opened in 2005. The new facility had state-of-the-art aseptic filling and monoclonal antibody manufacturing capabilities, both of which were in high demand due to limited capacity throughout the United States. This allowed the Laboratories to continue filling its own products, while simultaneously offering their resources for both private and public needs. Construction for a second facility adjacent to the first building began in 2009, and opened shortly thereafter. With the new buildings came a new name: in 2006, the Biologic Laboratories was officially renamed MassBiologics (MBL). By the summer of 2013, all functions of MBL were moved completely from the Jamaica Plain facilities to the new buildings in Mattapan, on land previously owned by the Boston State Hospital.101

Aerial Photo, 2004

MBL continued working on monoclonal antibodies, focusing their efforts on rabies and Hepatitis C. The rabies virus affects the central nervous system, and, left untreated, can cause brain disease and death. An editorial from the Bulletin of the World Health Organization noted that rabies is prevalent in southeast Asia, and that the “situation is especially pronounced in India, which reports about 18 000 to 20 000 cases of rabies a year and about 36% of the world’s deaths from the disease.”102 To develop the monoclonal antibody for the rabies virus, MBL again worked with Medarex and used their transgenic mice. The CDC’s recommended treatment for people who have not before taken the rabies vaccine is to take a combination of the vaccine and the human rabies immune globulin (HRIG).103 This treatment can be unaffordable for many; MBL’s monoclonal antibody is much more affordable, at less than one dollar a dose. A provisional patent was filed for discoveries related to rabies monoclonal antibody in February 2005.104 An agreement between MBL and the Serum Institute of India regarding the rabies monoclonal antibody was signed in 2006, and after the first clinical trials in 2009, MBL licensed the product to the Serum Institute.105 Simultaneously, “MBL was awarded both CDC pediatric and CDC adult contracts for sales of” the Tetanus-diphtheria (Td) vaccine.106

MBL’s monoclonal antibody for Hepatitis C virus (HCV) also went into clinical trials in 2009. HCV is one of the Hepatitis viruses that cause inflammation in the liver. HCV can be mild, as well as acute and chronic, causing lifelong health problems. Currently, there is no vaccine against HCV. The CDC notes that HCV “is the leading cause of cirrhosis and liver cancer and the most common reason for liver transplantation in the United States.”107 Unfortunately, a liver transplant will not cure HCV, and the residual disease will affect the new liver, putting the new liver at risk for cirrhosis and graft failure. The monoclonal antibody against HCV, which, when combined with new oral drugs, can potentially prevent virus replication after a transplant. The HCV monoclonal antibody is-as of 2014- currently undergoing Phase II clinical trials at multiple universities and hospitals throughout the US. In December 2013, MBL’s HCV monoclonal antibody received orphan drug status by the FDA.108

Opening the Doors for Research

In 2011, Dr. Ambrosino left MBL to work with the biotechnology company Visterra, and Terence R. Flotte, M.D., Executive Deputy Chancellor of the University of Massachusetts Medical School, acted as the Interim Director until Mark S. Klempner, M.D. became the Executive Vice Chancellor for MBL of the University of Massachusetts Medical School in 2012. Dr. Klempner joined MBL from the Boston University School of Medicine, where he served as Associate Provost for Research, Conrad Wesselhoeft Professor of Medicine, and was the founding director of the National Emerging Infectious Diseases Laboratories (NEIDL) at Boston University.

Dr. Klempner brought with him numerous opportunities for MBL to take on new manufacturing contracts. The June 2012 edition of BioTech Daily News noted that MBL opened “its doors to the research; translational medicine; and biopharmaceutical industries by providing access to its biological drug development and manufacturing expertise and capabilities.”109 For example, in July 2013, MBL was awarded a grant through Defense Advanced Research Products Agency (DARPA) to work with the University of Maryland School of Medicine’s Center for Vaccine Development in Baltimore. The 5-year grant supports research on Enterotoxigenic Escherichia coli (ETEC) antibodies that cause Travelers’ Diarrhea. MBL will make the monoclonal antibodies for the clinical studies conducted at the University of Maryland School of Medicine’s Center for Vaccine Development. This experiment will help in the understanding of the biology of this disease, and may eventually aid in finding a vaccine.110

MBL is now the only non-profit, FDA-licensed, vaccine manufacturing facility in the United States. MBL continues to support a mission of discovering and developing products that will significantly improve public health, as well as expanding on its historical legacy of products to include products to combat orphan diseases. Additionally, MBL supports the expanded provision of information, research, and products to developing nations with limited resources and unique needs.