Jet engine will drive expanded campus power plant

To make sure the lights shine brightly in the Albert Sherman Center, UMass Medical School is turning to high-efficiency jet power to expand the output of the campus power plant.

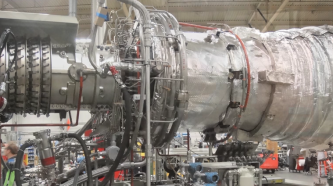

The $47 million project is adding nearly 14,000 square feet to the turbine hall on the south side of the power plant to accommodate a new 7.5 megawatt, gas-fired combustion turbine and associated equipment that will boost the plant’s capacity to generate steam, electricity and chilled water.

“The new turbine is a derivative of a jet engine,” said Joseph Collins, director of energy resources. “A conventional jet engine is designed to produce thrust. This turbine is designed to turn a generator and produce heat.”

The new turbine, a Taurus 70 being produced by Solar Turbines, is nearing completion at the company’s San Diego plant and will arrive on campus this spring. Fueled by natural gas, the turbine will spin a shaft attached to a generator to produce electricity. At the other end of the turbine, exhaust flowing at 910 degrees will be funneled into a heat recovery steam generator (HRSG) to produce some 60,000 pounds of high-pressure steam per hour. That steam will do triple duty: It will drive two of the plant’s existing electric generators, then move through the campus’ steam-line network to heat buildings and drive compressors that make chilled water for the campus’s cooling systems.

“We are called a cogeneration plant, because we get two outputs from one input,” Collins said. “The fuel is the input, and steam and electricity are the outputs.”

When the new gas turbine is operating, one of the plant’s original gas and oil-fired steam boilers will be taken off-line and kept in reserve as an emergency back-up. Since natural gas burns cleaner than oil, and the new jet turbine is highly efficient, the expanded power plant will actually have lower green-house gas emissions, despite its added energy capacity.

Furthermore, the new turbine will incorporate a catalytic reduction system to remove pollutants before the exhaust gasses are discharged through the existing smokestack. “We’ve designed this project to be supportive of our campus sustainability goals,” said John Baker, associate vice chancellor of facilities management. “The school and hospital operations continue to grow, but we want to do so in ways that limit our carbon footprint.”

Skanska USA is building the power plant project, which also includes construction of a new control room for the entire plant. When the expansion is completed, the plant’s maximum electrical output will increase from 10 to 17.5 megawatts. The existing plant produces all the steam and chilled water currently needed on campus, and about half of the electricity used. The expanded plant will be able to meet nearly all of the campus’s electrical demand, even after the opening of the Sherman Center, but the school will maintain a connection to the external utility grid to handle peak demand and for a back-up resource.

“We have critical needs for power, heating and cooling in the hospital and research labs year-round, so we are always concerned about redundancies and maintaining operations,” Collins said. “This plant has had about seven minutes of interruption in 35 years of operations, so I will say we’re pretty reliable.”

Construction of the plant expansion began last spring. The new turbine, HRSG and associated equipment are expected to be installed and ready for testing this fall.